The DER-IC network draws upon a broad range of capabilities to support industry partners, whether it is for product or manufacturing processes development.

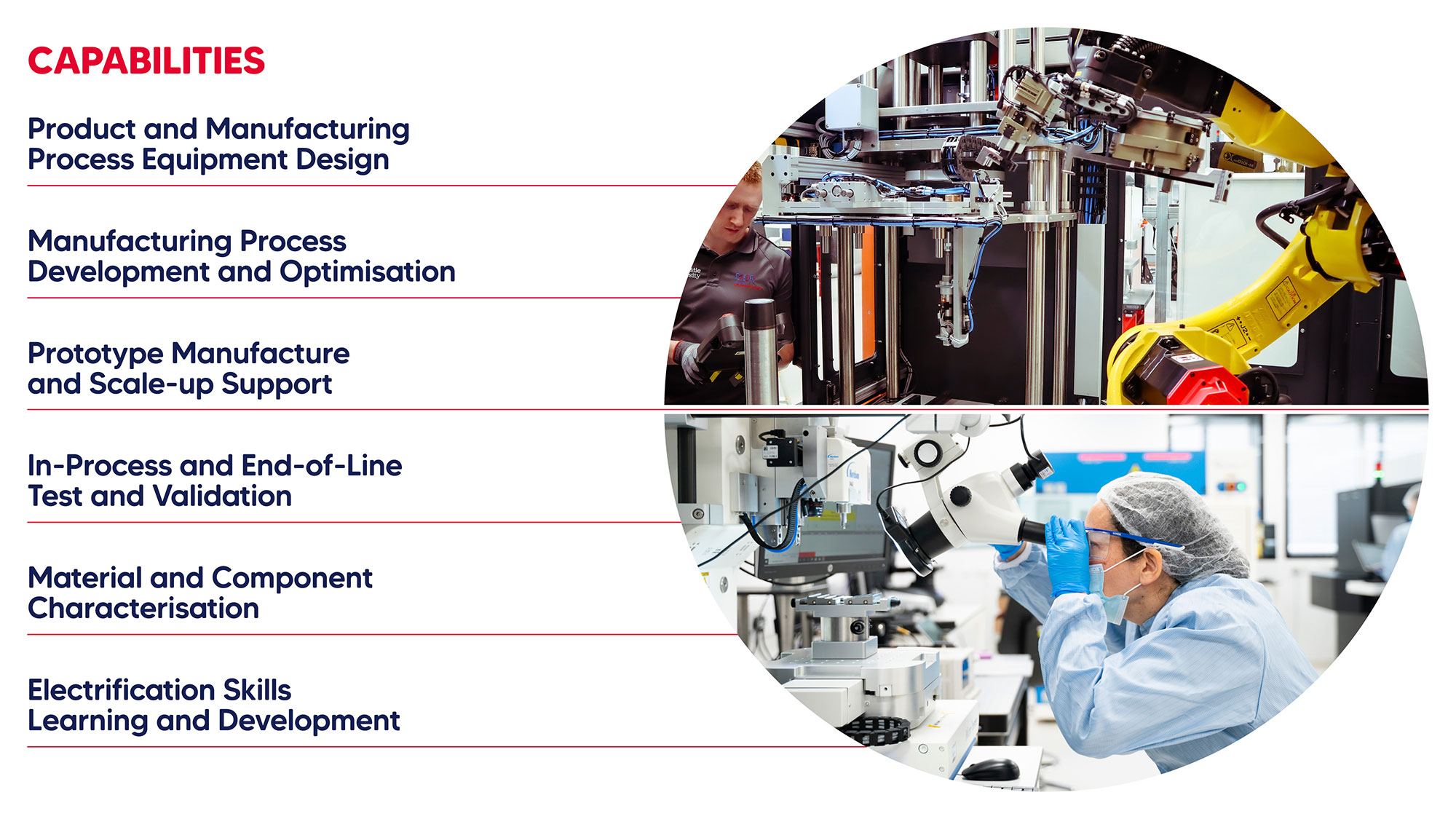

Product and Manufacturing Process Equipment Design

Design support for both product and manufacturing process equipment to develop effective solutions for specific requirements.

Manufacturing Process Development and Optimisation

Streamlining production workflows, improving quality control processes, and enhancing productivity – much of the DER-IC equipment is representative of volume manufacturing process, to accelerate and de-risk project delivery.

Prototype Manufacture and Scale-up Support

Smoothing the transition from prototypes to full-scale production, optimising manufacturing parameters, and integrating new technologies or designs into production.

In-Process and End-of-Line Test and Validation

Assuring the reliability and performance of products and systems, covering functional testing, performance evaluation and environmental testing at all stages of the production process with a ‘no fault forward’ approach.

Materials and Components Characterisation

The DER-IC network can draw on extensive facilities for the characterisation of materials and components used in PEMD. DER-IC equipment can help to analyse and evaluate the properties and performance of materials, components and joining technologies, enabling informed decision-making in material selection, quality control and design optimisation.

Electrification Skills Learning and Development

The DER-IC network provides a comprehensive package of electrification skills learning and development, working with the ER Skills Hub to enhance the knowledge and skills of professionals in the PEMD industry. This covers technical areas across all skill levels, including bespoke short courses for industry.